Chemicals for functional and decorative electroplating

Electroplating baths are used to apply precious metal containing compounds and their solutions in thin layers to surfaces. The surface then acquires the same properties as if it was made of solid precious metal, at a fraction of the cost. Depending on the area of application, the following advantages can result:

- electrical conductivity

- corrosion and temperature protection (due to insensitivity to oxidation)

- mechanical protection (due to hardness)

- optical attractiveness (due to gloss)

In electroplating, the precious metal solution is introduced into the electroplating bath as a precursor. The workpiece (surface) to be plated is placed as the cathode, and the corresponding precious metal as the sacrificial anode. The application of an electrical voltage leads over time to the formation of a thin precious metal coating on the cathode / workpiece.

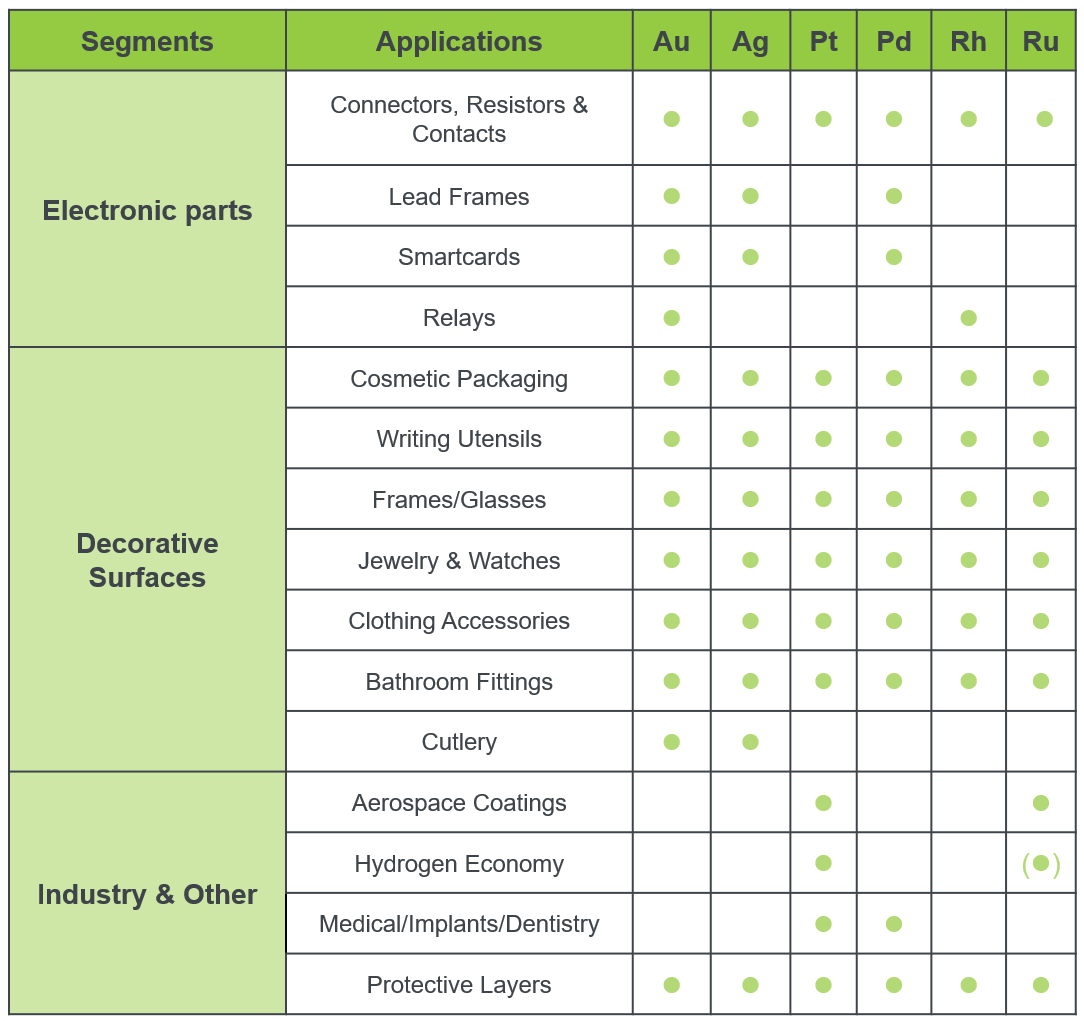

The main application areas of precious metal based electroplating include:

- Electronics industry

- Automotive industry

- Aerospace

- Jewelry bipolar plates in the hydrogen industry (e.g. fuel cells)

In the Heraeus Shop you will find the following suitable compounds and solutions for electroplating:

Tetrachloroaurate(III) sol. LSAMP Cis-Diamminedichloroplatinum | CAS: 14286-02-3 Rhodium Sulfate Solution | CAS: 10489-46-0 Palladium(II) Sulfate Solution | CAS: 13566-03-5 Dihydrogen Hexahydroxoplatinate | CAS: 51850-20-5 Palladium Chloride Solution | CAS:16970-55-1You can' t find the right product? You will find more suitable products on our website or in the Chemical Product Selector.

Website Chemical Product SelectorElectrode coatings and electrocatalysts

Electrochemical processes, i.e. chemical processes involving electric current, are part of the established large-scale syntheses in the chemical industry. Electrodes are used in order to transmit the current. Platinum group metals platinum, iridium, and ruthenium, but also silver, play the technically prominent role to produce these electrodes, due to their corrosion resistance and electrical properties.

In addition to electrodes, there are also electrochemical sensors, which are used for the detection of toxic gases (e.g. CO).

Precious metal coatings for corrosion protection of electrodes

Precious metal coated electrodes are used, for example, in chlorine alkali electrolysis, water purification, cathodic protection and in proton exchange membrane (PEM) fuel cells and electrolyzers.

Often times, these are industrial processes with particularly corrosive, oxidizing media or conditions. Coated anodes, so-called "DSA" (= dimensionally stable anodes) are used in these processes. The coating improves both the electrical properties of the anode and its resistance to corrosion. The precious metal compounds are usually applied as a solution, pyrolytically decomposed and then firmly bonded to the substrate material.

In the Heraeus Shop you will find the following suitable compounds and solutions that are used for coating or manufacturing electrodes for electrochemical processes:

Ruthenium Chloride Hydrate | CAS: 14898-67-0 Ruthenium Chloride Solution | CAS: 14898-67-0 Trinitratonitrosylruthenium | CAS: 34513-98-9 Trinitratonitrosyl Ruthenium(II) Solution | CAS:34513-98-9 Dihydrogen Hexachloroiridate Hydrate | CAS: 16941-92-7 Dihydrogen Hexachloroiridate Solution | CAS: 16941-92-7 Iridium Chloride Hydrate - Type G | CAS14996-61-3 Iridium Chloride Hydrate | CAS: 14996-61-3 Iridium Chloride Hydrate | CAS: 10025-97-5You can' t find the right product? You will find more suitable products on our website or in the Chemical Product Selector.

Website Chemical Product SelectorFunctional catalytic surfaces for electrodes

In some applications, the focus is not on corrosion protection, but on the function of developing a catalytic effect, i.e. initiating a chemical reaction through the precious metal. This is particularly the case in the hydrogen economy.

In proton exchange membrane (PEM) electrolysis, platinum and iridium are used to split water into hydrogen and oxygen. In order to make this application suitable for mass production, and to enable the production of hydrogen in the required quantities, catalysts require particularly good properties in terms of performance and reactivity. Heraeus anode catalysts are characterized by up to three times higher catalyst performance while reducing the precious metal loading in the electrode by 50-90% compared to previous generations.

Catalysts are also used in fuel cells. They generate electrical energy by direct, controlled chemical conversion of hydrogen with oxygen to water H2O.

In the Heraeus Shop you will find the following suitable materials used for the production of electrodes for hydrogen technologies:

Catalysts for PEM Electrolysis Catalysts for Fuel CellFor more detailed information and suitable products, please visit our website or the Catalyst Selector.

Website Catalyst SelectorCatalysts for electrochemical sensors

Electrochemical sensors are often used for the detection of gas hazards, for example oxygen deficiency or excess or toxic gases. Especially the latter are often very reactive – which electrochemical sensor makes use of. The gas reacts with the coated surface in the sensor membrane and electrons are generated. This results in a very small current which can be measured.

In the Heraeus Shop you will find the following suitable compounds and solutions used for coating sensor material for electrochemical sensors:

Platinum Black | CAS: 7440-06-4 Iridium Black | CAS: 7439-88-5You can find more detailed information and suitable products on our website.

WebsitePrecursors for the coating of supported catalysts

In 90% of all industrial processes, catalysts are used to start or improve chemical reactions. For the heterogeneous catalysts used in this context, precious metal is deposited onto a support material (e.g. alumina, carbon, etc.) in the form of a so-called precursor, e.g. precious metal containing solution or salt.

In the Heraeus Shop you will find the following suitable compounds and solutions which can be used as precursors for the coating of supported catalysts:

Chloroplatinic Acid Solid | CAS: 26023-84-7 Chloroplatinic Acid Solution | CAS: 16941-12-1 Catalyst Rhodium Trichloride HSAMP Rhodium Chloride Solution | CAS: 13569-65-8 Palladium Nitrate Hydrate | CAS: 10102-05-3 Palladium(II) Nitrate Solution | CAS: 10102-05-3 Platinum Nitrate Hydate | CAS: 18496-40-7 Platinum Nitrate Solution | CAS: 18496-40-7 Ruthenium Chloride Solution | CAS: 14898-67-0Additional precursors for supported catalysts can be found in our Chemical Product Selector.

Chemical Product SelectorHeraeus also offers a wide portfolio of supported catalysts with different carriers, different precious metal compounds and various loadings. You can find a selection of heterogeneous catalysts in this online shop and in the Catalyst Selector.

Heraeus Product Shop Catalyst SelectorDecorative and technical coatings for screen printing, brush application as well as other application methods

With the help of metallo-organic precious metal preparations, products can optically be refined (e.g. tableware) or technical applications can receive special functionalities (e.g. conductivity). The preparations are based on oil / resin systems (resinates) and give your product the essential finishing touch.

Decorative coatings are used to add special colour accents to substrates such as porcelain, ceramics or glass. Our precious metal color palette ranges from golden-yellow to platinum-silver to copper and rose. Depending on the product, a variety of application methods can be used. The most common methods are: Brush application, screen printing, edging, spraying, dipping and pad printing.

Coatings for technical application on the other hands are used for adding a certain functionality to the product. The coating can provide good conductivity, particularly clean surfaces or act as a heat shield within the application. Very thin layer thicknesses of 0.1 to about 0.5µm may be achieved and used, for example, in electronics or the automotive industry.

The preparations for coatings can also be applied through a number of different methods, e.g. brush application, screen printing, or spraying.

In the Heraeus Shop you will find the following precious metal preparations which can be used for technical and decorative coatings:

Further information on precious metal preparations for technical and decorative coatings can also be found on the Heraeus website.

WebsiteOther precious metal coatings

Ruthenium precursors for the semiconductor industry

With the ongoing miniaturization of interconnects between transistors, conventional materials such as copper are increasingly reaching their limits. Alternative materials have to be found that offer low resistance with fast switching times even at a very small diameter. At the same time, good properties in terms of robustness against thermal and electrical degradation are also needed. In this regard, ruthenium precursors show promising results. By applying atomic layer deposition (ALD) or chemical vapor deposition (CVD) interconnects can be produced that are only a few nanometers thick.

Information about precursors for the semiconductor industry can be found on our website.

WebsiteAntimicrobial coatings

Combating the effects of harmful microorganisms is an important issue in numerous areas of daily life and industry. For this purpose, Heraeus offers AGXX - an innovative antimicrobial technology - which offers many advantages over conventional antimicrobial solutions.

Information about AGXX can be found on our website.

WebsiteFurther precious metal coatings from companies of the Heraeus Group

Thick film materials for the electronics industry Metallic coatings by aerosol deposition Silver coatings for the photovoltaics industry