Refining or remelting? What is the right method for your needs?

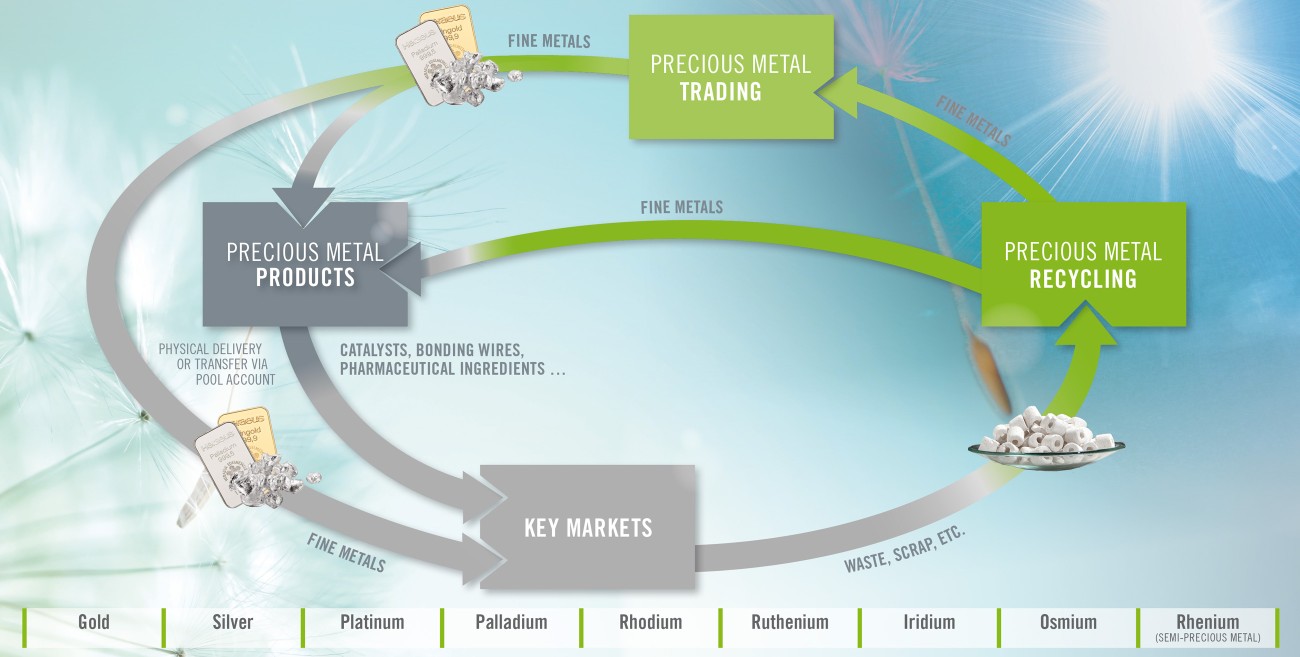

There are a variety of different methods for recovering precious metals. The method for the recovering your precious metal is determined by its chemical make-up and the impurities that are present. The most important difference is whether the precious metals- can be melted down and reused as an alloy, or whether a chemical recycling (refining) process is required to separate into the individual precious metals elements.

Precious metal materials that are returned and have a low level of impurities can be remelted (cleaned) in the smelter to purify the alloy. If the returned material needs to be de-alloyed (separated from each other), contain low levels of precious metals or are highly contaminated then it must be chemically refined (separated) from the other materials present.

Return of Precious Metals for Remelting

Heraeus will remelt precious metals in the smelter regardless of the manufacturer of the product. The purified alloy can be used to produce new products made up of the same alloy. However, it must be from an alloy that can be used for products that Heraeus normally produces.

Typical products that are processed by Heraeus are crucibles, lids, dishes, thermocouple wire, cuttings, components, stirrers, feeders, etc which are made up precious metals.

Frequently remelted metals and alloys include:

- 100% Platinum

- 95% Platinum, 5% Gold

- 90% Platinum, 10% Iridium

- 95% Platinum, 5% Rhodium

- 94% Platinum, 6% Rhodium

- 90% Platinum, 10% Rhodium

- 87% Platinum, 13% Rhodium

- 80% Platinum, 20% Rhodium

- 70% Platinum, 30% Rhodium

- 100% Iridium

- 100% Gold

- 92% Platinum, 8% Wolfram

For all of these alloys you can start a remelting order directly online. If you would like to send in a different alloy, please contact Customer Service.

If you wanted to trade in your old cracked or deformed crucible (or another product) and use the metal toward the purchase of a new one or store the metal for future use, the store is set up so that you can easily create a remelting order. Minimum order size is 50 grams of precious metal. If it is determined that the material is heavy in impurities Customer Service will contact you.

You can also send in precious metal independent of a purchase and use it later for a comparable product. You can also place product orders without sending in scrap material at the same time and have your products be manufactured from already existing precious metal stock or have the necessary precious metal purchased from Heraeus. When you buy a product in the store, you must decide if the required precious metal will come from your precious metal pool account, purchasing of the metal or a combination of the scrap material and the purchasing of new metal.

Once sufficient precious metal is secured, you can place the order. Note that scrap material must be received at Heraues before we can begin production.

How to Submit Remelt Orders Online.

The process for submitting a remelt order is simple:- First Step: Start a new order indicating that you wish to trade in precious metal (either while purchasing a product or an independent re-melt order).

- Second Step: Specify the alloy of your scrap material and fill out the questionnaire with the legally required information about composition, possible impurities and, if applicable, hazardous substances.

- Third Step: Click “submit” to place order. You will receive an address label with a consignment number for your scrap material from Heraeus by E-mail.

Once your material has arrived, been accepted and processed, the precious metal value will be credited to your precious metal pool account. You can view the status of your remelting order at any time via the "Remelting Orders" link.

Heraeus only processes industry-standard quantities of precious metal weighing 50g or more from companies. Private individuals cannot use our services. Please contact Customer Service if you have any questions. We will be happy to assist you.

Return of Precious Metals for Refining

As noted, above, in precious metal recycling, Heraeus processes materials that contain one or more precious metals as well as other chemical elements. The form and scope of the process depend entirely on the material composition and can be more complex. In addition, there are legal regulations for the shipment of precious metal waste that must be considered before and during transport. Therefore, processing of refining orders is usually more extensive and customer specific.

As noted, above, in precious metal recycling, Heraeus processes materials that contain one or more precious metals as well as other chemical elements. The form and scope of the process depend entirely on the material composition and can be more complex. In addition, there are legal regulations for the shipment of precious metal waste that must be considered before and during transport. Therefore, processing of refining orders is usually more extensive and customer specific.

Typical materials that are processed in precious metal refining at Heraeus:

- Alloys with high impurities or low precious metals concentrations

- Precious metal catalysts at the end of their life cycle

- Concentrates / Residues

- Precious Metal containing solutions

Process your refining order digitially through myHeraeus.com

Heraeus also provides support in managing all your precious metal needs with a specialized online platform tailored to the customer. With myHeraeus.com, you can process your recycling orders digitally in a way that is both convenient and professional.Learn about the benefits of myHeraeus.com or feel free to contact us!

myHeraeus.com

Request an account to create your remelting order

Request an account to create your remelting order